The Composition of Solar Panels and Recyclability

Solar panels play a pivotal role in the transition towards energy independence and renewable energy. Understanding the materials within solar panels will help understand their recyclability. It will also show the challenges associated with recycling the components that solar panels currently require. This knowledge is essential for ensuring the sustainability of solar energy systems. Let’s delve into the composition of solar panels, the recyclability of their materials, and the hurdles in recycling these components effectively.

Materials in Solar Panels

- Silicon Solar Cells

Purpose: Convert sunlight into electricity.

Silicon solar cells are the heart of a solar panel. They are made from silicon, a semiconductor material. These cells turn sunlight into electricity. This happens when photons from sunlight hit the silicon cells. The photons knock electrons free, which then flow to produce electricity. Silicon is chosen for several reasons. It’s abundant, non-toxic, and has great photovoltaic properties. This makes it ideal for solar cells. Silicon solar cells have two layers. One is n-type silicon with extra electrons. The other is p-type silicon with extra spaces for electrons, called “holes”. Sunlight creates electron-hole pairs in the cell. These generate an electric current when connected to an external load.

- Glass

Purpose: Protects solar cells, typically made of tempered glass.

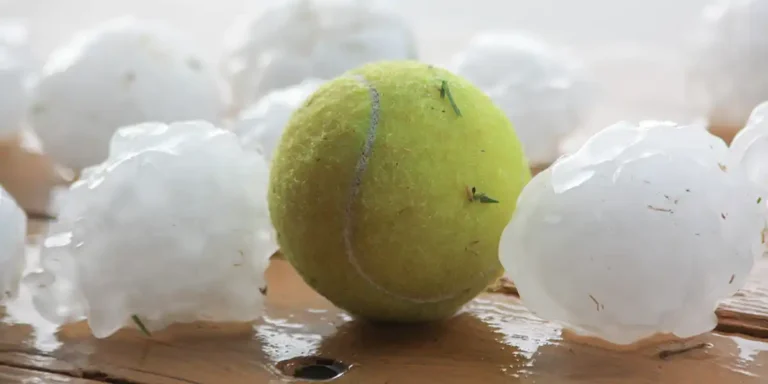

Glass is used to protect solar panels for good reasons. It’s very durable, clear, and resists weather damage. Tempered glass can withstand hail, snow, rain, and extreme temperatures. It does this without breaking or becoming less clear. This toughness keeps the solar cells safe for a long time. It also helps the panel work well. Glass is also very clear. This lets most sunlight reach the silicon cells. The cells then turn this light into electricity. Other materials like plastics could protect solar cells too. But they don’t last as long or let as much light through. They can break down, turn yellow, or become cloudy when exposed to sun and weather. This would make the panel less efficient and not last as long. So, glass remains the best choice for covering and protecting solar cells.

- Aluminum Frame

Composition: Provides structural support and protection.

Aluminum is used for solar panel frames because of its good qualities. It’s very strong for its weight. This means the frames can be light but still tough. They support the panel without making it too heavy. This is important when installing solar panels. It’s especially crucial for large groups of panels or roof installations. Too much weight could cause problems. Aluminum also doesn’t rust easily. This helps the panels last longer, even in harsh weather. Its resistance to rust keeps the panel’s structure strong over time. This helps the panel keep working well for many years.

- EVA Encapsulant

Composition: Laminates solar cells, protecting them from environmental factors.

EVA, or Ethylene-Vinyl Acetate, is used to seal solar cells in panels. It binds the glass and backsheet together. This creates a protective pocket for the cells. EVA is used because it sticks very well. It makes a tight seal around the solar cells. This seal keeps out moisture, dust, and other things that could harm the cells. EVA is also very clear. This lets sunlight reach the solar cells without much loss. It doesn’t get damaged easily by UV light or temperature changes. These qualities help solar panels last longer and work reliably.

- Backsheet

Purpose: Acts as a barrier to protect solar cells, composed of various materials.

The backsheet is a key part of a solar panel. It’s the outer layer on the back. It protects the solar cells and inner parts from damage. This includes moisture, dirt, and physical impacts. The backsheet also helps insulate the panel electrically. This makes it safer for people installing or using the panels. Different materials are used to make backsheets. These include polyvinyl fluoride (PVF), polyethylene terephthalate (PET), and polyamide. These materials are chosen for specific reasons. They resist UV light, moisture, and high temperatures. They’re also strong and provide good electrical insulation. Using different materials allows customization of solar panels. This helps them suit different environments better. Some materials are better at resisting UV light. This is important in very sunny places. Others provide better electrical insulation. This is needed for high-voltage setups. Having these options helps make solar panels work well in many situations. This contributes to making solar energy more sustainable and effective.

- Metals (Silver, Copper, etc.)

Purpose: Used in wiring and connections.

Metals like silver and copper are very important in solar panels. They conduct electricity extremely well. Silver is often used as a paste. It’s applied to silicon cells to make conductive grid lines. These lines collect and move the electrons that the solar cells produce. Silver’s great conductivity means very little energy is lost in this process. This makes the electricity production more efficient. Copper is used differently. It’s common in the wiring and connections of solar panels. It carries electricity from the panel to the inverter. From there, it goes to the power grid or storage. Copper works well in different weather conditions. It lasts a long time too. Using these metals is key to making solar panels work well. They help make solar panels efficient and reliable. This is important for making solar energy a good power source.uting significantly to their overall performance and the viability of solar energy as a sustainable power source.

Recyclability of Solar Panel Materials

- Silicon Solar Cells Recyclability

Recycling silicon solar cells starts with heat treatment to separate reusable parts. About 80% of components can be directly reused. The rest, including silicon particles or wafers, undergoes further processing. Wafers can be dissolved with acid or melted down if broken. This method achieves an 85% recycling rate for silicon material.

Recyclability: Easy process of melting and purifying for reuse.

- Glass

After disassembly, glass is cleaned and sorted by quality and thickness. It’s then crushed and melted at high temperatures (around 1500°C). Nearly 95% of the glass can be repurposed. External metal parts are used to remake cell frames.

Recyclability: Easily melted and reshaped without quality loss, using less energy.

- Aluminum Frame

Cleaned aluminum frames are melted to remove impurities and shaped into ingots or billets. These can be used to make new aluminum products, like solar panel frames. About 95% of the aluminum content is repurposed, making the process efficient and eco-friendly.

Recyclability: Efficiently melted down and reused, supporting sustainability.

- EVA Encapsulant

Recycling EVA is challenging due to its composition and how it’s used in panels. It’s hard to separate from other components without causing damage. EVA is sensitive to temperature changes, making careful heating necessary. Maintaining quality and purity of recycled EVA is crucial for reuse. Up to 80% of EVA can be recycled and reused in new applications.

Recyclability: Possible but needs special processes for separation and reuse.

- Backsheet

Backsheets are hard to recycle due to their complex makeup and construction. They have multiple layers of different materials, often laminated together. Separating these layers during recycling is difficult. Adhesives and coatings make it harder to extract recyclable materials. There are no exact figures on how much of the backsheet can be reused.

Recycling Challenge: Multiple materials and complex layering make straightforward recycling difficult.

- Metals (Silver, Copper, etc.)

Recycling metals like aluminum, copper, and silver from solar panels is efficient and well-established. These metals are easier to extract compared to other panel components. Aluminum can be melted and reshaped without quality loss. Copper and silver are recovered through chemical or electrolytic processes. Recycling these metals is cost-effective and reduces the need for new material extraction.

Recyclability: High, with good processes for recovery and reuse, though separation can be challenging.